14:05 - 14:10

KEMELStern Tube Seal Knowledge

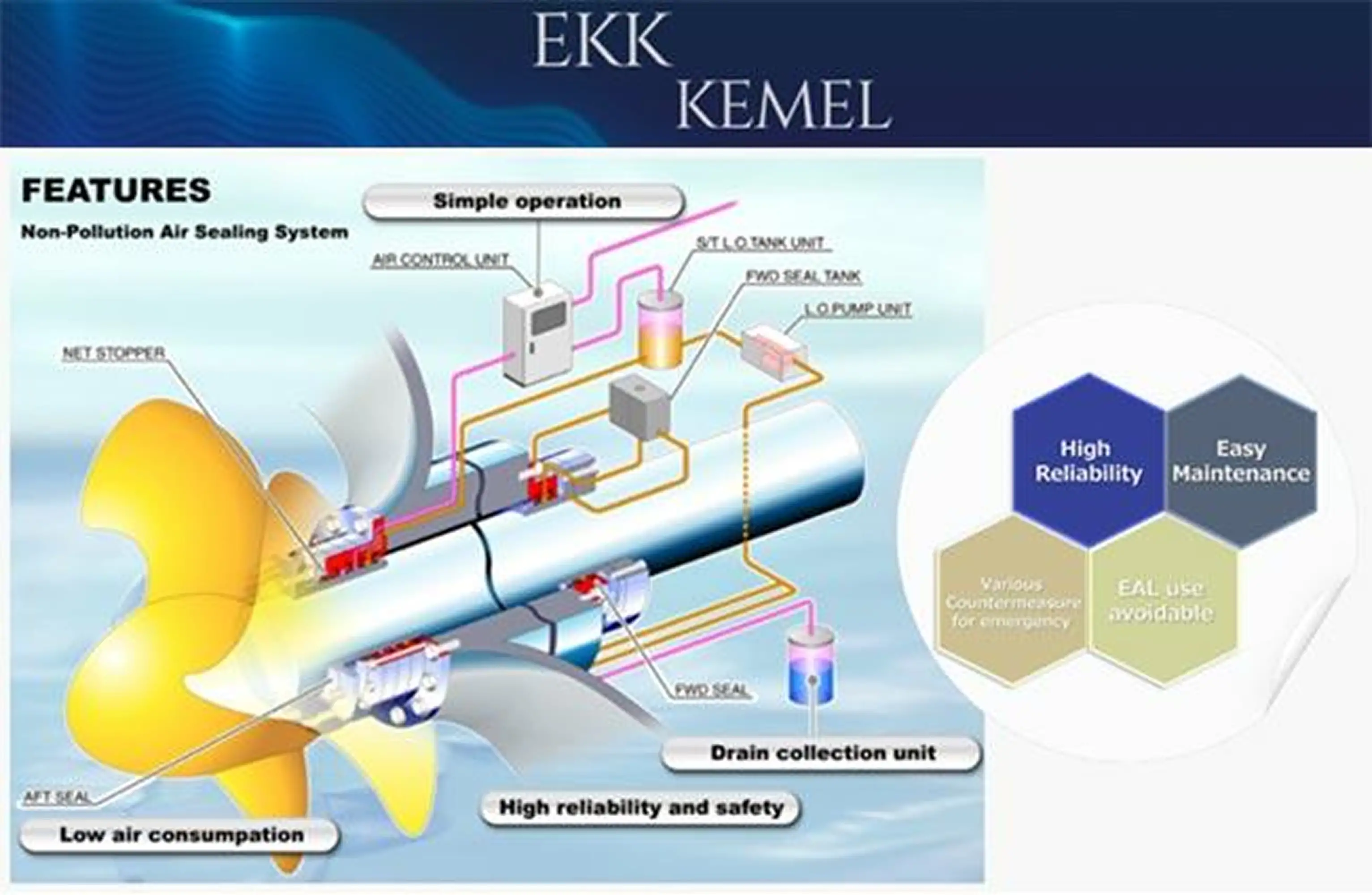

AIR SEAL (AX) NON-Pollution Air Sealing System

AX-Type (AIR SEAL)

The AX type Air Seal has a simplified structure. Air, supplied from the air source within the ship, passes through #2/3 chamber and is spouted into the sea water. Any change of draft is automatically detected by the air control unit and pressure is adjusted to maintain the optimum pressure on each part.

1. High reliability

High reliability is realized with the following two measures;

*Small pressure difference on all seal rings.

*The provision of two seal rings on sea water side and stern tube oil side. Even if the oil seal rings are damaged the leaked oil is completely collected in an air chamber between seal rings.

2. Easy Maintenance

Any draft change is automatically detected and the stern tube pressure changes in accordance with draft changes even on vessels with numerous draft changes due to loading conditions.

3. Low Air Consumption

Total air consumption is less than 40 Nl/min.

4. Various Emergency Measures

Emergency measures include spare seal rings and air control devices. It is possible to convert from air seal systems to Double security type compact seals with simple valve operations.

5. EAL is not necessarily used

*Stern tube oil and water are kept in non-contact.

*Suitable for VGP rules.